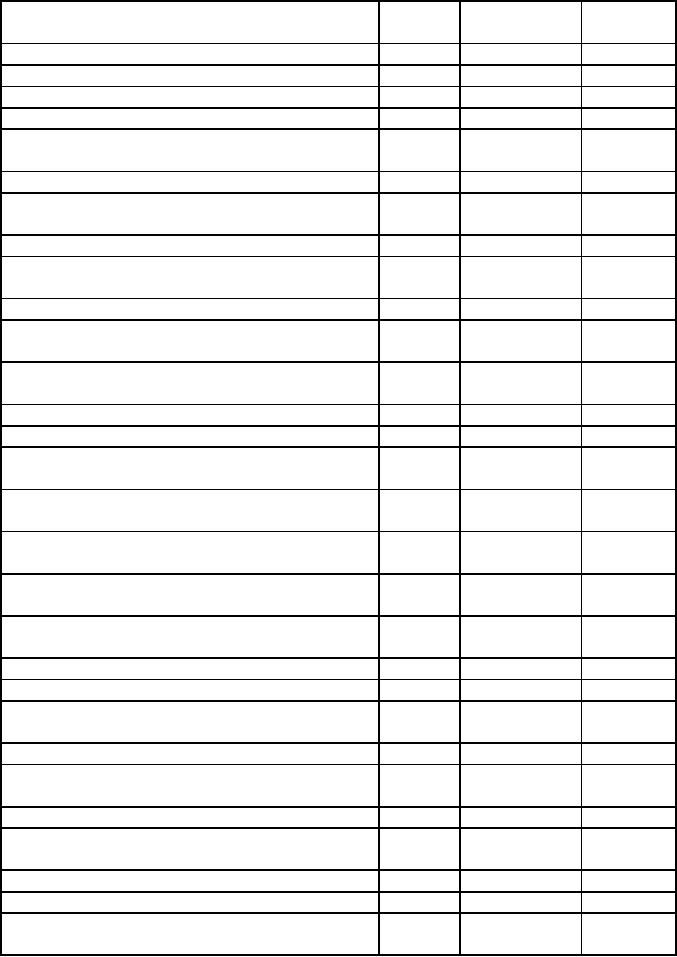

FED-STD-791D

Compatibility of synthetic air craft turbine

3433

lubricants with silicone rubber

Compatibility of turbine lubricating oils

3403.2

Contamination in engine oil

3006.3

None

Navy

Corrosiveness of emulsifyable cutting fluids

5306.5

Corrosiveness of grease(copper strip, 100░ C)

5309.5

Corrosiveness of greases or semi-solid products

5304.5

at 25░C

Corrosiveness of lubricants at 232░C (450░F

5305.1

Corrosiveness of oil on a bimetallic couple

5322.2

ASTM D

ARMY

6547

Corrosion of lead by lubricating oils

5321.2

Corrosion protection by coating : salt-spray (fog)

4001.3

test

Corrosion protection (humidity cabinet)

5329.2

Corrosion protection of steel against sulfurous

5331.1

acid- salt spray by solid film lubricants

Corrosiveness and oxidation stability of aircraft

5307.2

D 4636

AF

turbine engine lubricants

Diluted pour point

204.1

None

Navy

Dirt content of grease

3005.4

Determination of particulate matter in aerospace

3012

hydraulic fluids

Determination of particulate contamination in

3013

synthetic turbine engine lubricants

Deposit- foaming tendencies of aircraft turbine

5303

lubricants

Evaporation loss of lubricating greases and oils

350.2

(high temperature)

Extreme pressure properties of lubricants (four

6520.1

D 2783

NAVY

ball tester)

Effect of evaporation of flammability

352.1

Evaporation

353.1

Emulsification tendencies of petroleum fuels by

550.1

multiple contact extractions

Explosive vapors in boiler fuel oil

1151.2

Emulsion (petroleum and petroleum like

3201.7

products)

Emulsion(soluble cutting oils)

3205.3

Fatty oil in cutting oils by infrared

3110.1

spectrophotometry

Film thickness of dry solid film lubricants

3816.1

Flock point (refrigerant compressor oil)

1303.2

None

NAVY

Foaming characteristics of air craft turbine

3214.1

NONE

AF

lubricating oil (dynamic foam test)

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business