FED-STD-791D

flammability, handling and storage precautions, emergency treatment and measures, and

spill practices of each chemical are explained.

5.2 Test panel, chemical-lead grade (ASTM B 29-55 or equal) 3.5 H 4.13 H 0.16

cm (1-3/8 H 1-5/8 H 1/16 in), conforming to Table I.

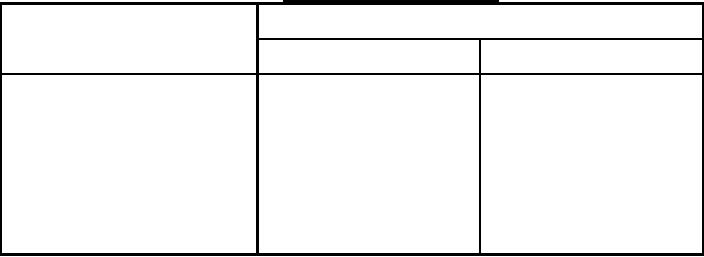

TABLE I. Composition of lead test pane.

Element

Content percent

Maximum

Minimum

Silver

0.020

0.002

Copper

0.080

0.040

Arsenic, antimony, and tin

0.002

-----

(total)

0.001

-----

Zinc

0.002

-----

Iron

0.005

-----

Bismuth

-----

99.90

Lead (by difference)

5.3 Test panel, copper, electrolytic (ASTM B 152/152M, 3.5 H 4.13 H 0.130 cm

[1-3/8 H 1-5/8 H 0.051 in] [16 gage]).

5.4 Naphtha, petroleum (TT-N-97).

5.5 Acetone (ASTM D 329).

5.6 Steel wool.

5.7 Pads, absorbent-cotton.

6. PROCEDURE

6.1 Preheat and adjust bath to 163░ " 1░C (325░ " 2░F).

6.2 Pour 500 mL of the sample into a clean sample tube, and place tube into the

bath so that the bath level is at least 2.5 cm (1 in) above the sample level.

6.3 Connect air supply line to the aerator intake of the sample tube.

6.4 Allow approximately 30 min for the specimen to come to test temperature.

6.5 Drill a 3/16-inch hole in the center of each test panel (see 5.2 and 5.3).

6.6 Polish and clean the test panels (handling only with forceps) as follows:

305

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business