FED-STD-791D

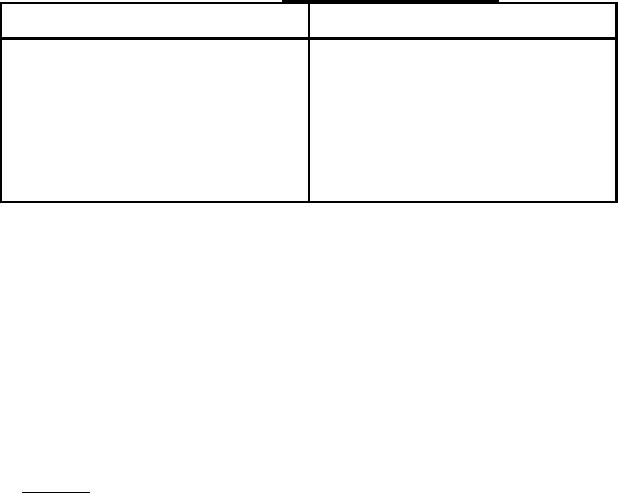

TABLE I. Standard operating conditions.

Condition

Value

Coking-tube temperature, ░C (░F)

(590░ 5░)

310░ 2.5░

"Oil-in" temperature, ░C (░F)

149░ 2.5░

(300░ 5░)

Air temperature (test section), ░C (░F)

48.9░ 2.5░

(120░ 5░)

300 5

Oil flow, mL/min

Air flow, mL/min

300 5

Oil level (aerated), below top of

3.81 0.32

(1-1/2 1/8)

coking-head glass, cm (in)

6.15 Using the standard operating condition listed in Table I, conduct a 12-hour

(10 min) run on the test oil used in adjusting the system (see 6.14). Perform the test as

follows:

a. While the system is hot, adjust the oil level in the oil filter tube to about 3.8 cm

(1-1/2 in) below the oil level mark on the tube (to allow for an increase in

volume as a result of aeration).

b. Start the oil flow at 300 mL/min.

c. Adjust the air flow to 300 mL/min.

d. Fill the oil feeder flask completely with test oil, stopper tightly, and install in oil

filler tube.

NOTE 5:

The feeder flask must be full at the start of the test run (to minimize oil

ejection due to air expansion). It is helpful to heat flask and oil to 54.4░C

(130░F) prior to its installation. The stopper on the flask must be tight to

avoid air leakage after installation.

e. Set coking tube temperature control to 310░C (590░F).

f. Check setting of "oil-in" temperature control for 149░C (300░F).

g. As soon as "oil-in" temperature reaches 138░C (280░F) start timing the test

period by setting the timer (4, see Figure 1) on 12 h. If apparatus is so

equipped, set watt-hour meter (5) to zero. Read and record all temperatures and

pressures.

h. Adjust height of oil-filler assembly to maintain the aerated oil level in the

coking head at the mark on the coking-head glass to within 0.32 cm (1/8 in).

Maintain this level for duration of test. Keep valve (29) open for duration of

test.

i. Check the operation of the coking-tube temperature control, and adjust to hold

310░ 2.5░C (590░ 5░F) coking-tube temperature. If the control does not hold

within these limits, adjustment of the band width is required. (See instruction

manual for the control).

j. Check "oil-in" temperature control, and adjust to hold 149░ 2.5░C (300░

5░F) "oil-in" temperature. If the "oil-in" control does not hold within prescribed

275

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business