FED-STD-791D

e. Add 1 g reagent grade barium carbonate (BaCO3). Stir solution, cover and place

in dark area for 4 h.

f. Decant and discard precipitate.

g. Add 1 g hydrochloric acid. Stir solution, cover and store in dark area until bath

solution is required for plating.

4.2.4 Plating apparatus. The following apparatus is required for plating the test

gear:

a. Ring stand or other suitable rack from which the wire gear holder may be

suspended.

b. DC power supply (6 to 8 V with variable power output of 0 to 20 A).

c. Nickel bar stock, approximately 5 15 0.64 cm (2 6

1/4 in), is used for

electrodes in the nickel strike and nickel plate bath.

d. Sheet lead, approximately 15 20 0.32 cm (6 8 1/8 in) thick, is used for

electrodes in the black chrome plate bath.

e. Plastic covered, 9 gage, copper wire is used to connect the power supply to the

electrodes.

4.2.5 Plating conditions. The following conditions are used for the strike and

plating baths:

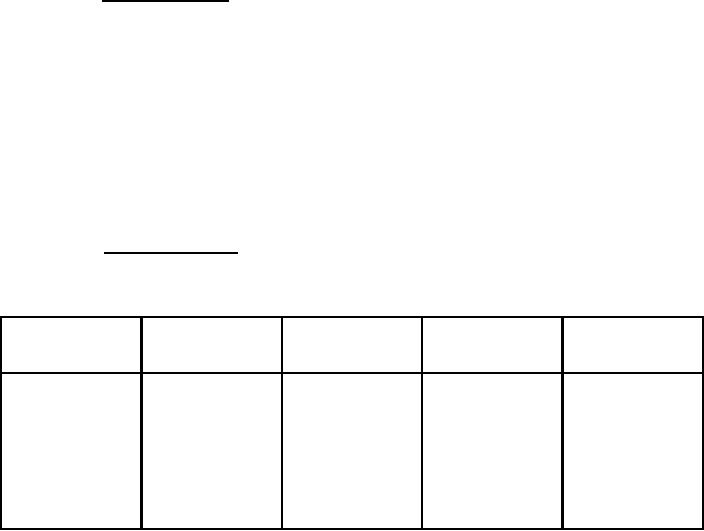

Plating time,

Solution

Gear polarity

Power, A

temperature

min

68.3░ 2.8░C

Nickel strike

2

0.5

Positive

(155░ 5░F)

Nickel plate

6

0.5

Negative

68.3░ 2.8░C

(155░ 5░F)

Black chrome

13.0

Negative

20

29.4░ 2.8░C

plate

(85░ 5░F)

5. MATERIALS

5.1 CAUTION - SOME MATERIALS ARE TOXIC AND HAZARDOUS. The

materials references and standards listed in this section must be handled carefully.

Federal Test Method 10000, Material Handling Safety Precautions, is a reference which

lists all toxic and hazardous materials cited in FTMS 791. The synonyms, life hazard,

flammability, handling and storage precautions, emergency treatment and measures, and

spill practices of each chemical are explained.

5.2 Lubricating oil, MIL-PRF-7808 or SAE J1966.

5.3 Dry cleaning solvent (A-A-59601D).

369

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business