FED-STD-791D

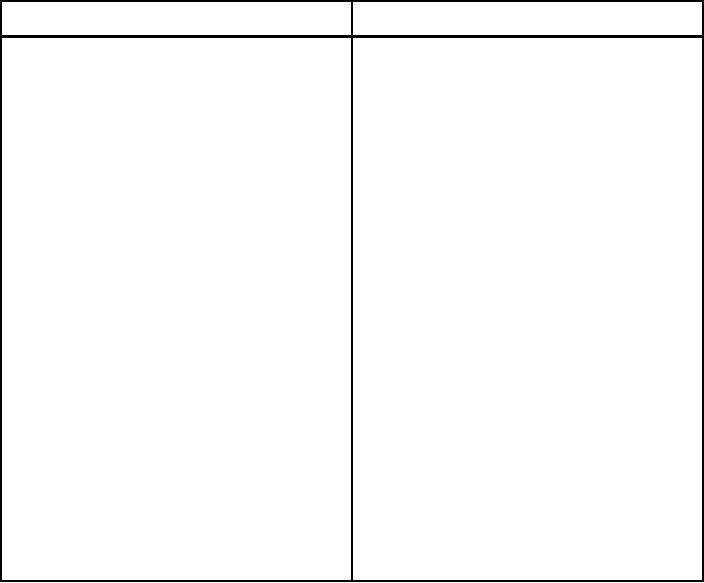

TABLE I. Operating Conditions.

Condition

Value

220° ± 2.8°C

Test gear temperature

(428° ± 5°F)

Test gear speed, rpm

10,000± 10

Test-oil inlet temperature

205° ± 2.8°C

(401°± 5°F)

Test-oil flow rate, mL/min

(271± 5)

Test-oil pressure

103.4 ± 34.5 kPa gage

(15 ± 5 psig)

Support-oil inlet temperature

73.9° ± 2.8°C

(165°± 5°F)

Support-oil pressure

To load-oil system

827.4 ± 69 kPa gage

(120 ± 10 psig)

To step up gearbox

To WADD gear machine

241 ± 34.5 kPa gage

(35 ± 5 gage)

Airflow to seals

0.33 ± 0.047 L/sec

(0.70 ± 0.10 cfm)

6.1 Test Procedures

6.2 Preparation for test.

1. Turn on main electric switch and main water valve to test cell.

2. Push instrument button to "ON" position.

3. push support oil sump heater button to "ON" position.

4. Turn radiometer function switch to "READY" position.

5. Turn on power supply to induction heater and place induction heater filament

switch in "ON" position.

6. Inspect test oil system to see that it was thoroughly cleaned and dried after

previous test.

7. Remove gear case end cover.

8. Clean a set of new plated test gears with petroleum ether, and dry with air.

9. Measure gross tooth width of the narrow test gear with a micrometer, and record

371

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business