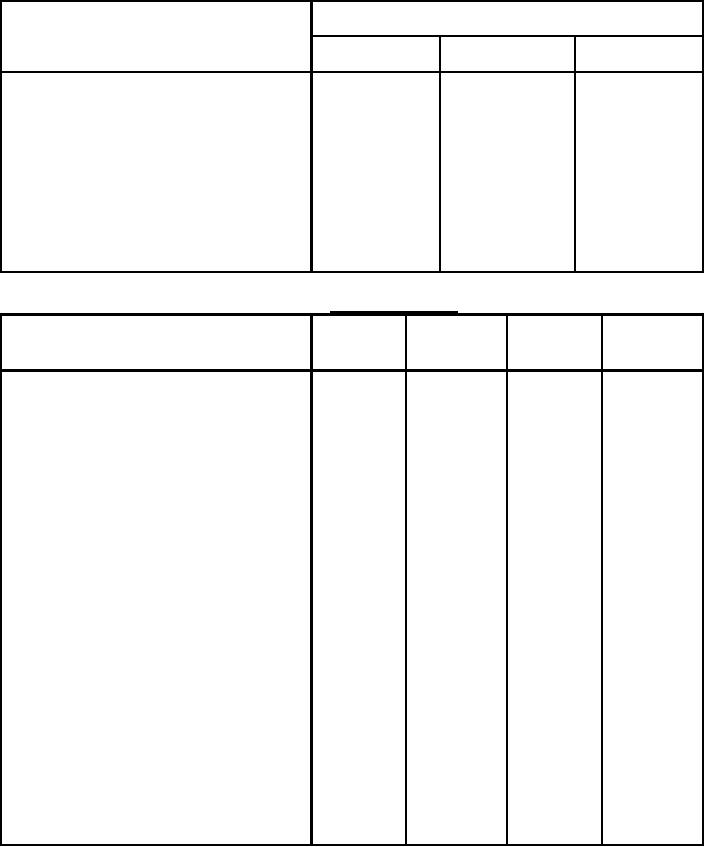

FED-STD-791D

TABLE I. Operating conditions for different severity levelsof Erdco high temperature bearing

test.

Type

Condition

1

1-1/2

2

Test oil-in temperature, ░C

149░ " 2.5░

177░ " 2.5░

204░ " 2.5░

Test tank bulk oil temperature, ░C

171░ " 2.5░

199░ " 2.5░

227░ " 2.5░

Test bearing temperature -max., ░C

260░ " 2.5░

260░ " 2.5░

260░ " 2.5░

Air flow to end cover, L/min

9.9 " 1.4

9.9 " 1.4

9.9 " 1.4

Test oil-in temperature, ░F

350░ " 5░

300░ " 5░

400░ " 5░

Test tank bulk oil temperature, ░F

340░ " 5░

390░ " 5░

440░ " 5░

Test bearing temperature -max., ░F

500░ " 5░

500░ " 5░

500░ " 5░

Air flow to end cover, CFM

0.35 " 0.05

0.35 " 0.05

0.35 " 0.05

TABLE II. Critical test items.

Minimum

Maximum,

Minimum

Maximum,

, cm

cm

, in

in

1. Dimensional tolerances

a. Test bearing outer race fit in heater

-0.00051

-0.0002

0

0

mount

b. Test bearing inner race fit in heater

-0.0020

-0.0008

mount

c. Axial run-out of front vertical face of

0.000

0.000

testbearing outer raceassembled in

rig

d. Screw type seal

0.046

0.018

2. Electrical connections

a. Test bearing heater. This is a

single wrapped 4700-W unit

which should be connected to

220-V power source.

b. Test oil tank immersion heater.

This unit is made up of three

1,500-W heaters which should

be series-connected to a 220-V

power source.

6.5 Operating conditions.

126

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business