FED-STD-791D

2. Repeat steps 1 through 3 of the shutdown procedure

3. Reduce load on bearing completely.

4. Allow the test oil tank temperature and the oil-in temperature to reach 138░C (280░F)

and 121░C (250░F) respectively. Maintain these temperatures.

5. When the test temperatures stabilize, run for one hour and monitor the maximum

temperature of the test bearing.

6. Record the highest bearing temperature.

7. Shut off bearing drive motor.

8. Repeat step 5 of the shutdown procedure.

6.7 Demerit system for rating deposits in Erdco bearing machine.

6.7.1 Outline of method.

6.7.1.1 Cleanliness demerits. Bearing head cleanliness shall be reported in this demerit

system by the assignment of values of 0 to 20 to the inspection results, as follows:

0 shall designate a new or thoroughly clean condition.

20 shall represent the worst condition that could be expected.

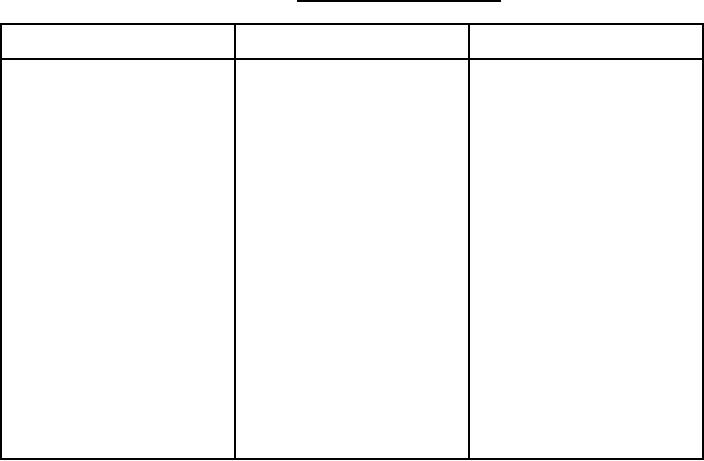

6.7.1.2 Table III shows the numerical demerits to be assigned to different types and

degrees of deposits:

TABLE III. Deposit rating demerit scale

Type of deposit

Degree

Demerit values

Flaked carbon

Heavy

20

Moderate

19

Light

18

17

Blistered carbon

Heavy

Moderate

16

Light

15

Heavy

14

Crinkled

Moderate

13

Light

12

Smooth carbon

Heavy

11

Moderate

10

9

Light

Sludge

Heavy

8

Moderate

7

Light

6

Varnish

Heavy

5

Moderate

3

Light

1

135

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business