FED-STD-791D

19.

Start the support oil pumps; there should be at least 414 gage kPa (60 psig) manifold

pressure. At the screw thread seal there should be at least 0.8 cm (0.3 in) of oil

positive pressure relative to the support oil side (manometer leg to test compartment

lower).

20.

Set and maintain the support oil pressure at 552 to 689 gage kPa (80 to 100 psig) by

means of a regulating valve.

Allow oil temperature at the support scavenge line to reach at 38.8░C least (100░F).

21.

Start the bearing drive motor; the bearing speed is preset at 10,000 rpm. (If bearing

22.

drive is not constant speed, follow motor operating instructions to bring it up to the

necessary speed.)

23.

Turn off the load by-pass switch.

Apply a load to the test bearing. Increase the load on the bearing gradually with the

24.

load controls. The load cylinder pressure should be held at 352 gage kPa (51 psig).

Continue running until the following conditions have been stabilized:

25.

121░ " 2.5░C

(250░ " 5░F)

Test oil-in temperature

138░ " 2.5░C

(280░ " 5░F)

Test tank bulk oil temperature

(0.35 " 0.05 ft3/min)

Air flow, end cover

9.9 " 1.4 L/min

(corrected)

(corrected)

Make at least two separate flow checks of one-minute duration each at the three-way

26.

valve position on the pressure side of the scavenge pump. The measured volume

flow rate should be 600 " 30 mL/min. The hot test oil collected during the flow

check should be poured immediately back into the test oil tank through the fill port

and the port recapped.

27.

Continue running for one hour at these conditions with the bearing heater off. If

during or at the end of this period, the maximum bearing temperature has exceeded

177░C (350░F), shut down the rig, install a new test bearing, and repeat items 1

through 26. If the maximum bearing temperature has not exceeded 177░C (350░F)

during this period, proceed with the next step.

28.

Turn on the test bearing heater and adjust indicator flag to the target temperature on

the temperature controller.

29.

Check the three test bearing outer-race thermocouples to make sure that the second

highest indicating thermocouple is connected to the temperature controller. Maintain

260░C (500░F) on the highest indicating thermocouple

30.

Adjust the test oil tank thermal switch so that the target temperature for the type of

test being run is met within 30 minutes (minimum) and 60 minutes (maximum).

Maximum heater skin temperature should not exceed 29░C (85░F) above test oil

target temperature during the warmup period. The nozzle temperature should be

maintained at 177░ " 2.5░C (350░ " 5░F).

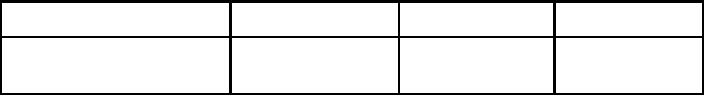

Test type

1

1-1/2

2

171░ " 2.5░C

199░ " 2.5░C

227░ " 2.5░C

Target temperature

(340░ " 5░F)

(390░ " 5░F)

(440░ " 5░F)

132

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business