FED-STD-791D

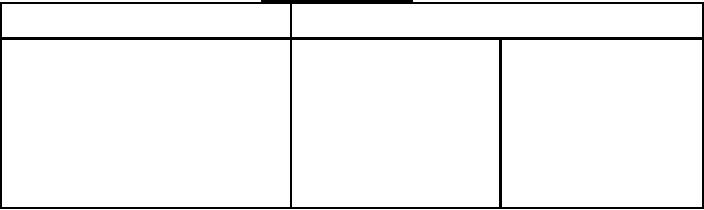

TABLE I. Operating conditions.

Condition

Value

10,000 10

Test gear speed, rpm

165░ 5░F

73.9░ 2.5░C

Test oil inlet temperature

270 5 mL/min

Test oil flow rate

165░ 5░F

Support oil inlet temperature

73.9░ 2.5░C

Support oil pressure

110 10 psig

758 69 kPa gage

Step-up gear box pressure

25 to 30 psig

172 to 207 kPa gage

Support oil chamber vacuum

1 to 4 in of water

2.5 to 10.2 cm of water

6.2 Preparation for test.

1.

Record pertinent information such as test number, test oil code, operator's

name, etc., on suitable data sheets (Figure 11).

2.

Turn on main electric switch to test cell.

3.

Turn on main water valve to test cell.

4.

Push instruments button "ON".

5.

Push support oil heaters button "ON".

6.

Make sure that the test oil system has been thoroughly flushed with Stoddard

solvent and petroleum ether after the last test. See 6.3.2 steps (17) through

(25) for the flushing procedure. Use the flushing solvent once and discard.

7.

Remove gear case end cover.

8.

Inspect shaft seals. Replace with new seals if necessary.

Inspect shafts for any nicks or other damage in the area of the seals. Damage

9.

must be repaired before machine is used for testing.

Clean a set of new test gears with dry cleaning solvent and discard solvent.

10.

Measure gross tooth width of the narrow test gear, and record the

measurement.

Install test gears with the serial number facing outward, matching timing

11.

marks on shafts and gears. (See Figure 5.) Check for proper seating of the

retaining nut, and lock the lock washer.

12.

Install new O-ring in position.

13.

Reinstall gear case end cover.

14.

Start test oil pressure pump.

15.

Flush test oil system with test oil, as follows:

a.

Turn 3-way valve L to "DRAIN".

b.

Turn 3-way valve M to running position.

c.

Turn 3-way valve N to running position.

d.

Fill test oil sump with about 750 mL of test oil. Watch drop of level in sump.

Allow 400 mL to drain through L.

e. Drain the next l00 mL by opening drain K also. Then close drain K.

f. Turn valve L to running position, so as to permit flushing of that section of

the test oil system between valve L and sump.

341

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business