FED-STD-791D

amount of contamination with test oil, which can be determined from periodic laboratory tests

on support-oil samples.

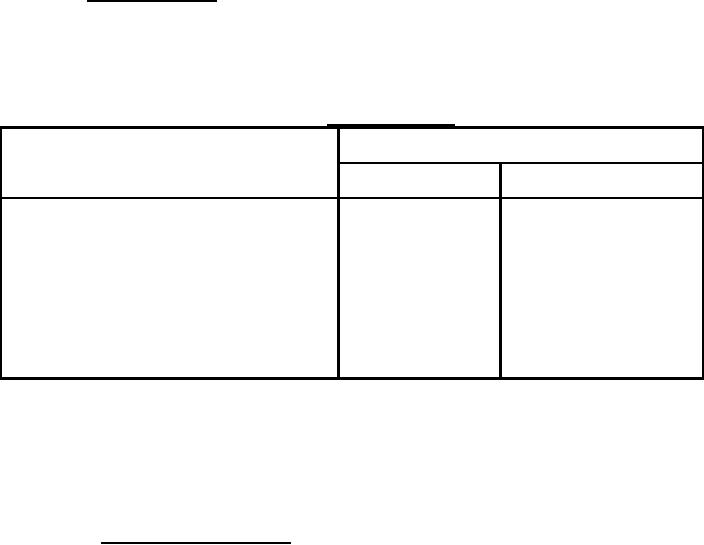

6.4 Critical test items. Before starting a test, care should be taken that critical test items

conform to the tolerances listed in Table I.

TABLE I. Critical test items.

Item

Dimensional tolerances in cm (in)

Minimum

Maximum

Test-bearing outer race fit in heater mount

-0.0005

0.00018

(0.0002)

(+0.0007)

Test-bearing inner race fit on hub

-0.002

-0.0036

(-0.0008)

(-0.00014)

Screw seal diametral clearance

0.046

0.056

(0.018)

(0.022)

Test-oil jet

0.099

0.104

(0.039)

(0.0041)

6.5 Operating conditions.

6.5.1 Throughout the entire test, the test-oil-in temperature, bulk oil temperature,

test-bearing temperature, and airflow to the end cover are controlled at the values required by the

applicable lubricant specification.

6.5.2 Initial test-oil flow setting. The test-oil sump is charged with 7.75 L (2 gal) of the

test lubricant at room temperature and heated to a temperature of 126.7░C (260░F). Air to the

end cover is set at 0.165 L/sec (0.35 cfm). The test- and support-oil pumps are turned on and the

main drive motor actuated to a speed of 10,000 rpm. The rig speed should be brought up

immediately after oil circulation is started as the screw-thread seal depends on relative motion

for its sealing action. The previous setting on the test-oil pressure pump or a minimum of 68.9

kPa gage (10-psig) oil pressure at the jet is used to insure against possible oil starvation during

this initial startup. The pressure drop across the seal is maintained at 0.76 to 1.27 cm (0.3 to 0.5

in) of test oil by making fine adjustments to the gearbox vent valve. As soon as a 121.1░C

(250░F) oil temperature at the jet has stabilized, a minimum of two separate flow checks of

1-min duration each should be made at the incorporated test oil flow measuring system. The oil

pressure at the jet should be adjusted using the variable speed drive unit on the test-oil pump

until the jet oil flow is 600 mL/min. Once the flow rate of 600 mL/min is established for an oil,

the flow at this condition is maintained constant during the test. The observed test-oil flow rate

is checked and recorded once every 3 h, or when indicated by any irregularities in test operation.

182

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business