FED-STD-791D

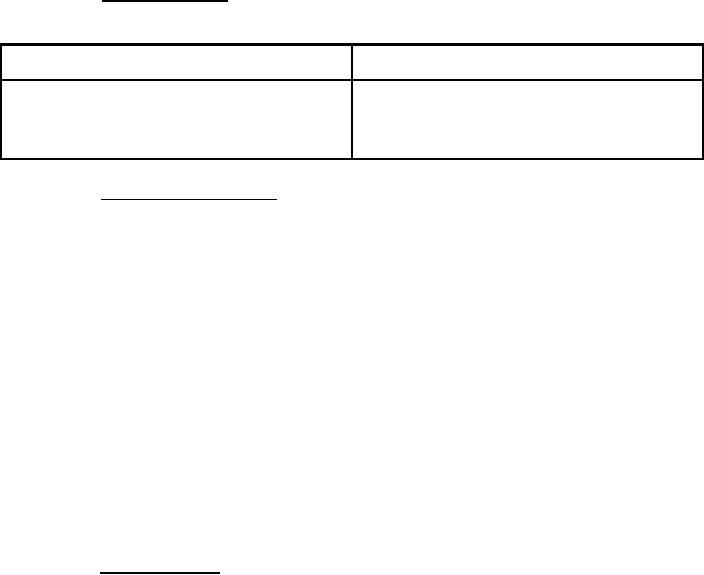

6.5.5 Used oil analysis. The following laboratory tests are run on the new and used oil

samples:

Test

ASTM method

Viscosity at 37.8░C (100░F), cSt

D 445

Viscosity at 98.9░C (210░F), cSt

D 445

D 446, using a pH 11 endpoint

Neutralization No., mg KOH/g

6.5.6 Test-oil flow rate check. During operation, the test-oil flow rate is checked at the

incorporated test-oil flow rate measuring system once every 3 h. The system is located in the

scavenge line as shown on Figure 2. It consists of a three-way valve located in the scavenge line

which permits routing of the oil into an open 1000-mL separatory funnel. The funnel stopcock

tube leads to a two-way valve which connects to the scavenge line.

6.5.6.1 The test-oil flow measuring procedure is carried out by setting the three-way

valve to route the oil into the funnel for a period of 1 min, at which time the valve is reset to its

normal position. After the oil volume is measured, the two-way valve and stopcock are opened

to drain the oil in the funnel back into the scavenge line. The two-way valve and stopcock are

closed after the oil is drained in preparation for succeeding test-oil flow rate determinations.

Care is taken to prevent air entering the scavenge line upon draining the separatory funnel.

6.5.6.2 At the completion of the test, while the test oil is still hot, the sump and test-oil

system is drained into a suitable container so that the volume of test oil remaining can be

determined. After the volume of test oil has been measured (room temperature) and recorded, 1

L (1 t) of the test oil should be poured into a clean container and saved for laboratory analyses.

6.5.7 Rig photographs. As soon as practical, the rig is disassembled and 10

12.7 cm (4

5 in) color photographs are taken of the following components:

a. Bearing compartment with cover removed - front view.

b. Heater mount - rear side.

c. End cover - rear side.

d. Seal plate in housing - heater and bearing removed.

e. Test bearing - inner race, rollers, and cage assembly close-up, 45░ angle, 0░

position.

f. Test bearing - inner race, rollers and cage assembly close-up, 45░ angle,

180░ position.

g. Test bearing - outer race close-up, inside diameter, 0░ position (adjacent to

test-oil jet).

h. Test bearing - outer race close-up, inside diameter, 180░ position.

A typical set of photographs, reduced and in black and white, is shown on Figure 5.

184

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business